Unlike carbon steel, stainless steel maintains its passive protective film even in chloride rich environments, preventing rust, cracking, and spalling. This translates to service life exceeding 100 years, even under aggressive exposure conditions.

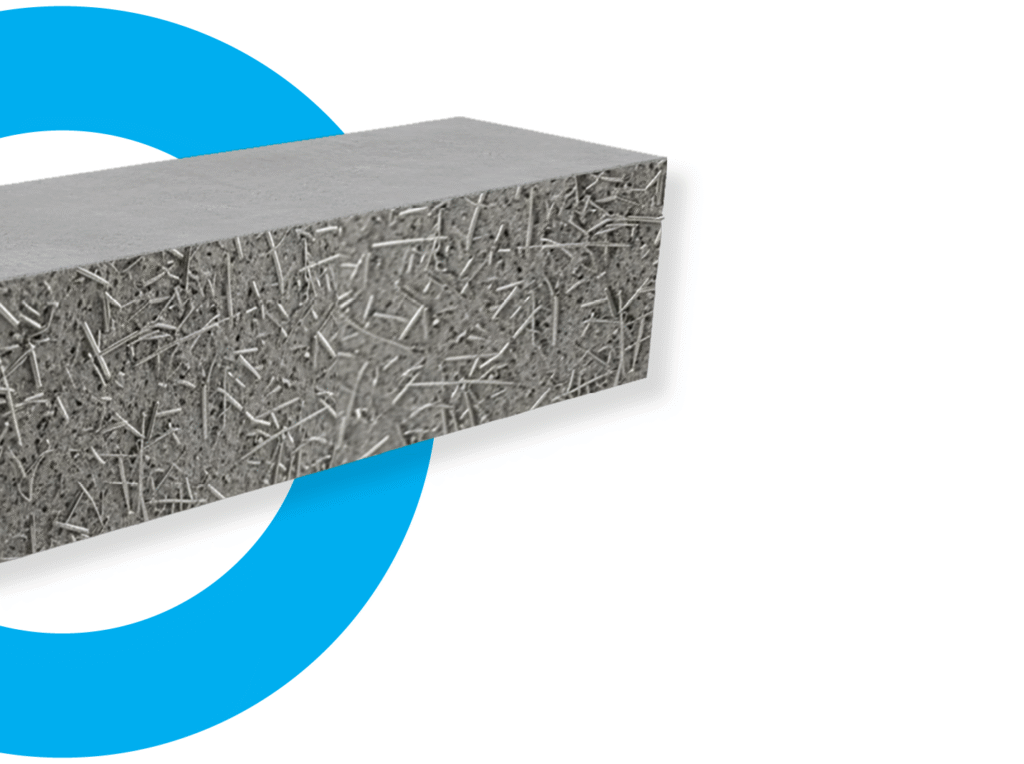

| Application Type | Dosage Range (kg/m³) | Volume Fraction (%) |

|---|---|---|

| Industrial Floors | 20–40 | 0.25–0.5 |

| Structural Elements | 40–60 | 0.5–0.75 |

| Shotcrete Applications | 30–50 | 0.38–0.64 |

| Precast Elements | 25–60 | 0.32–0.75 |

| High Performance Applications | 60–100 | 0.75–1.25 |

Add directly into mixers or via automated systems.

They reduce secondary reinforcement and control cracking; structural reinforcement depends on design codes.

Yes, per shipment.